Dynamic Projection System in Industrial 4.0 site assembly.

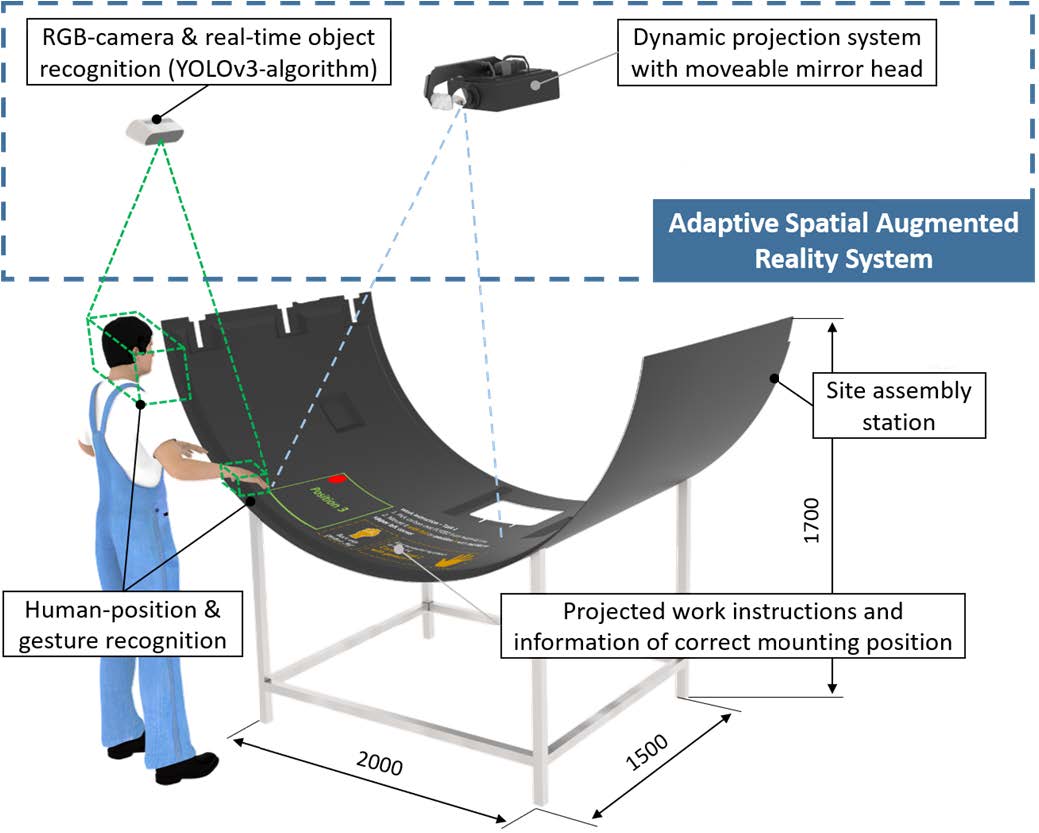

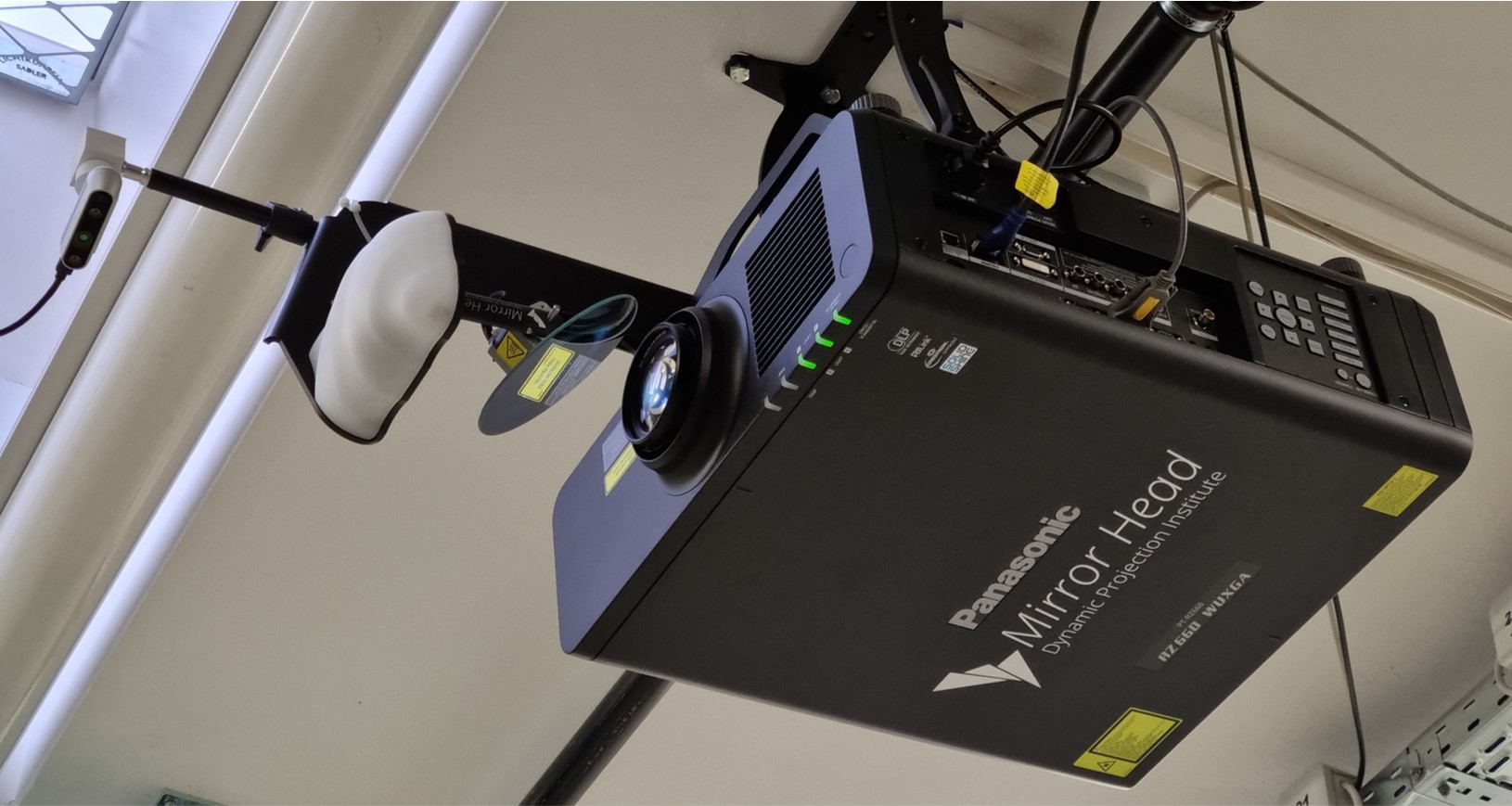

“The ability to project work instructions anywhere within a large work area is a key component of industrial spatial augmented reality systems. We thus consider the mirror head system, developed by Dynamic Projection Institute, an enabler for interactive work instructions, driving future improvements and providing benefits for both workers and industry.”

Univ. Prof. Dr.-Ing. Sebastian Schlund, BMK Stiftungsprofessur für Industrie 4.0, TU Wien

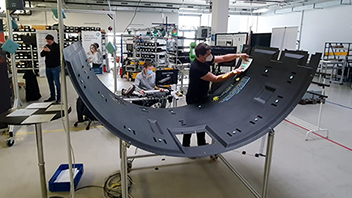

Today, industrial assembly of large equipment is often organized as site assembly. Information is provided on paper or stationary PC-terminals and employees have to walk long distances to receive information.

An augmented dynamic projection system allows direct display of work-instructions and interaction on the component. The paper presents the results of an evaluation of a dynamic projection system compared to state-of-the-art information provision. The experiment is carried out using a demonstrator with a CFRP-layup site assembly for aircraft components. The results show that the augmented dynamic projection system brings significant advantages for process improvements and usability compared to PC-terminals.

Publication: “Information provision utilizing a dynamic projection system in industrial site assembly“ on the occasion of 53th CIRP Conference on Manufacturing Systems in ScienceDirect.

Dynamic Projection Institute was present for an experiment using the spacial augmented reality system to build up a Lego castle. It is always with a certain pride that we discover all the possible applications of the Mirror Head.

Left to right: Hans Kueffner-McCauley BSc, Martin Willner, Head of Software Engineering and Thomas Kühne, Managing Director at Dynamic Projection Institute, Patrick Rupprecht, MSc MSc MA,.